Food Safety Performance Benchmarking: Charting Your Course in the Global Market

Last week, Agroknow hosted an very insightful webinar on the application on Food Safety Benchmarking. In the webinar, Angela Ferhati, Key Account Manager at Agroknow, was joined by Carmella H. Rashed, Global Director of Regulatory Affairs at Bimbo QSR and Iraklis Posnakidis, Senior Lead Software Engineer at Agroknow.

The main question that was posed for them was: how can food & beverage companies benchmark their food safety performance with precision?

Few of the topics that were discussed were:

- Which are some typical metrics and KPIs food & beverage companies use to measure food safety performance?

- How do they compare these performance metrics with other companies and brands in their market or industry?

- Is there a way to automate the process of collecting, combining, processing and visualizing the data in order to review how you stand towards the global food safety standards?

- What are some horizon scanning tools that can help this process?

- What are some Use Case Scenarios from FOODAKAI’s Benchmarking module?

Key Takeaways

In the course of the busy discussion between the four panelists, they went on to converse about how food safety performance metrics and tools vital for companies as they impact their competitiveness, risk management, compliance and overall strategic direction, through 3 powerful Use Cases from FOODAKAI.

Highlights of the discussion included:

- The webinar’s audience voted that the number of recalls and number of incidents related to specific hazard types are very critical KPIs when measuring their food safety performance.

- Dealing with the rapidly changing regulatory atmosphere especially since 2019 is an important factor that necessitates food & beverage companies to monitor food safety and know where they stand and where the hazards originate from.

- Maintaining of Consumer Trust and preventing reputational damage a top priority to food companies for performing food safety performance benchmarking.

- Lack of industry synergies for certain food safety topics (such us the accepted/established allergic food MRLs from country to country), gaps in suppliers’ information (e.g., ingredient specification data, COAs) and import and export activities about food safety requirements constitute a great challenge for food safety performance procedures for food companies.

- The webinar's audience voted that the number of incidents related to specific type of hazard and products followed as the most critical KPI when measuring their food safety performance of their competitors.

- Noting the importance of monthly updates on the company’s food safety performance KPIs and performing benchmarking frequently.

- How the real-time availability of data can promote cross-continental collaboration in food companies with teams worldwide.

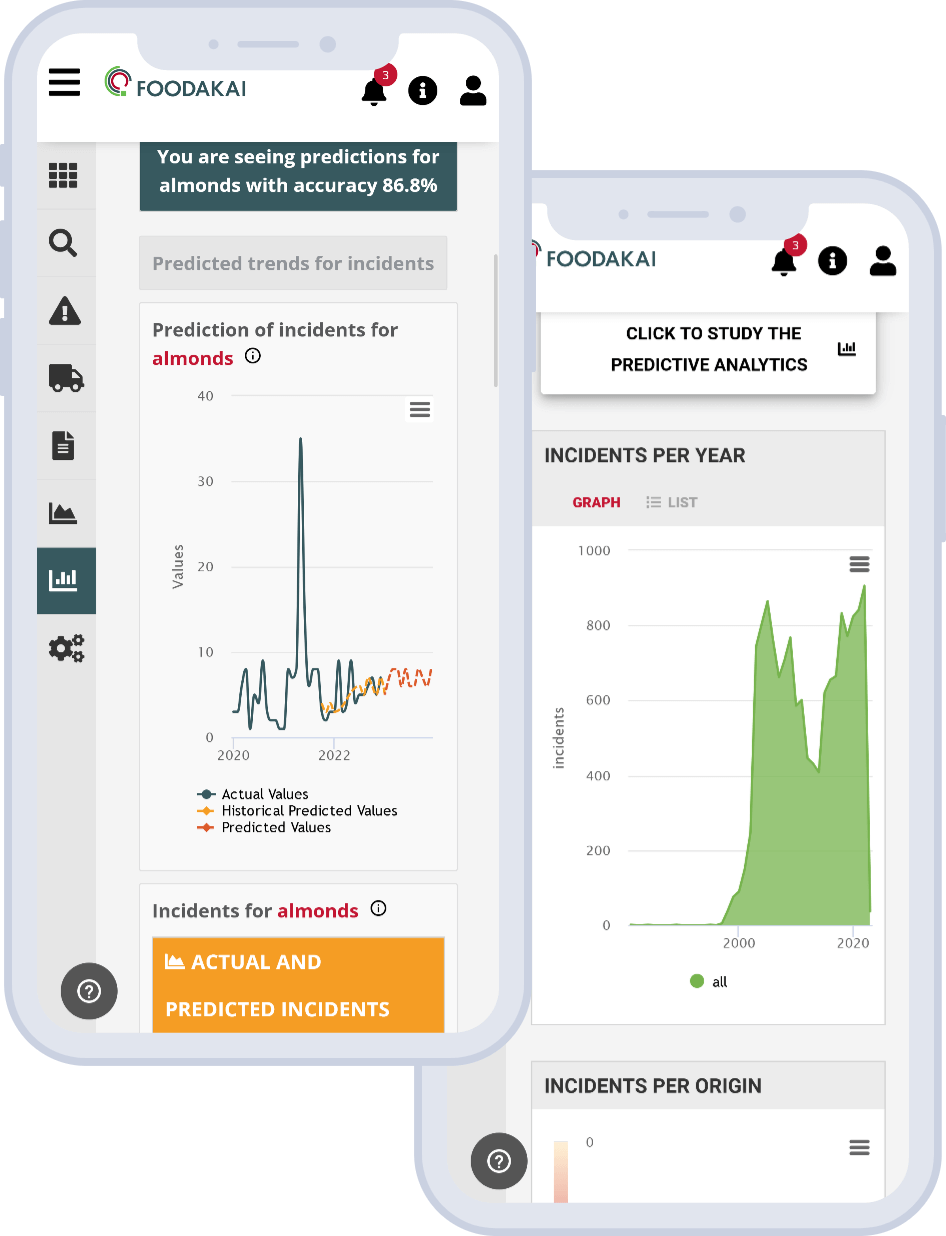

- FOODAKAI’s food safety performance benchmarking capabilities for food companies, their brands, for specific industries, competitors or markets through 3 analytical use cases.

FOODAKAI’s Benchmarking Use Case

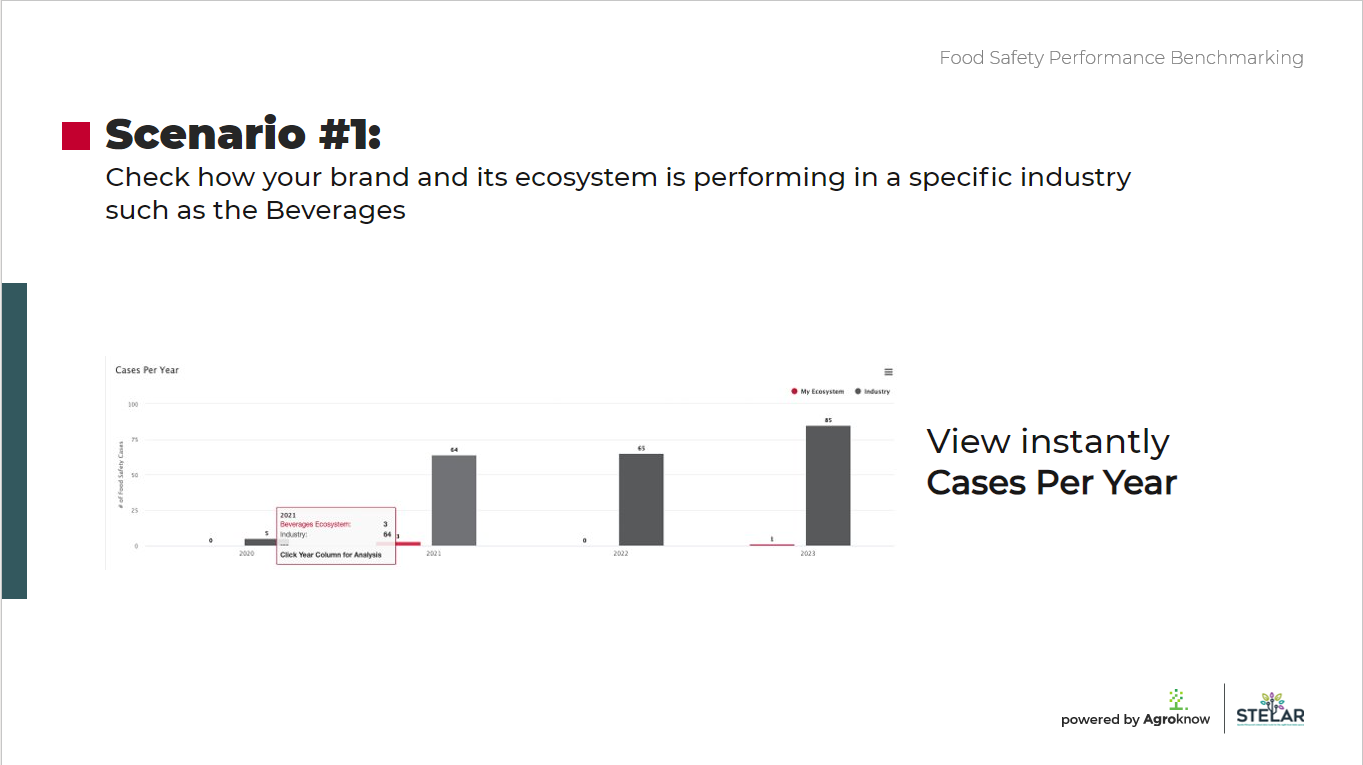

1 . Examine how your brand/subsidiaries and ecosystem performs in a specific industry

Through FOODAKAI’s Benchmarking module food & beverage companies can set up ecosystem lists corresponding to their own ecosystem (e.g., beverages ecosystem), competitors’ ecosystem (e.g., beverages competition) and determine their industry or market by selecting ingredient and product groups. This way they can benchmark their company’s ecosystem against the whole industry for their selected products.

Food companies can have an overview of then of the food safety performance of their company against the industry through analytical charts of Cases/Incidents Per Year their company or industry in general were involved in. Thus, they can understand where they stand compared to the whole industry.

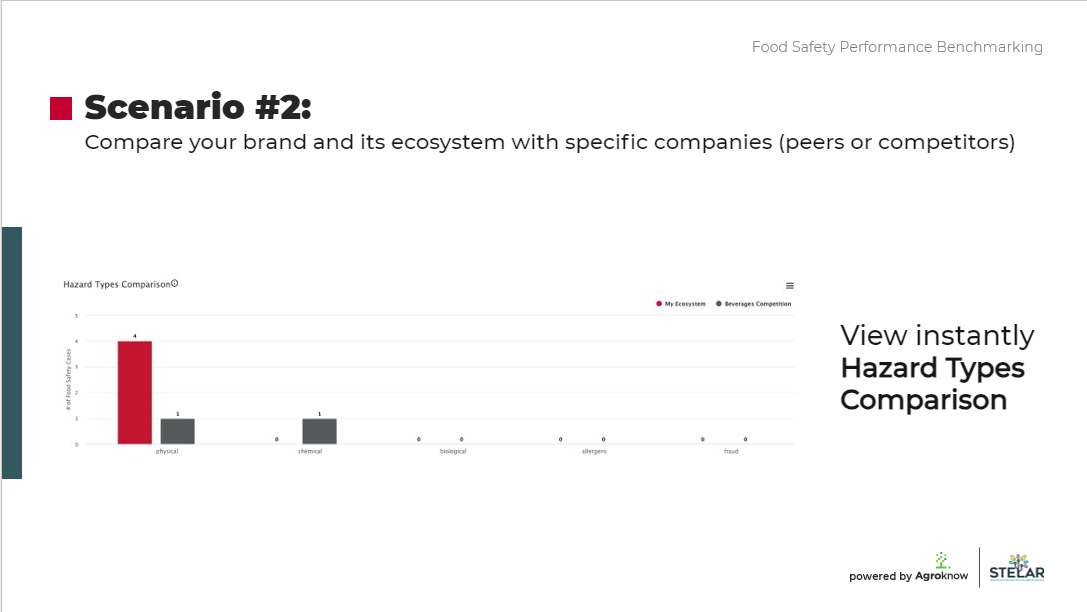

2. Compare your brand against specific peers or competitors

Having set their own and their competitors’ ecosystems as well as their market (ingredients and product groups), food companies can perform comparative analysis of one of their brands against their competitors. In this case, after selecting their own ecosystem and ingredients or product groups they want their comparison about they can specify their competitors they want to benchmark their food safety performance against.

Using FOODAKAI’s benchmarking module food companies, in addition to the cases/incidents for the past years their brand or competitors were involved in, can also drill down further to view the hazard types associated to these cases/incidents with easy-to-share charts. This would allow them to have a more in-depth view for which hazard types their company’s and competitors’ ingredients and products had been more vulnerable to.

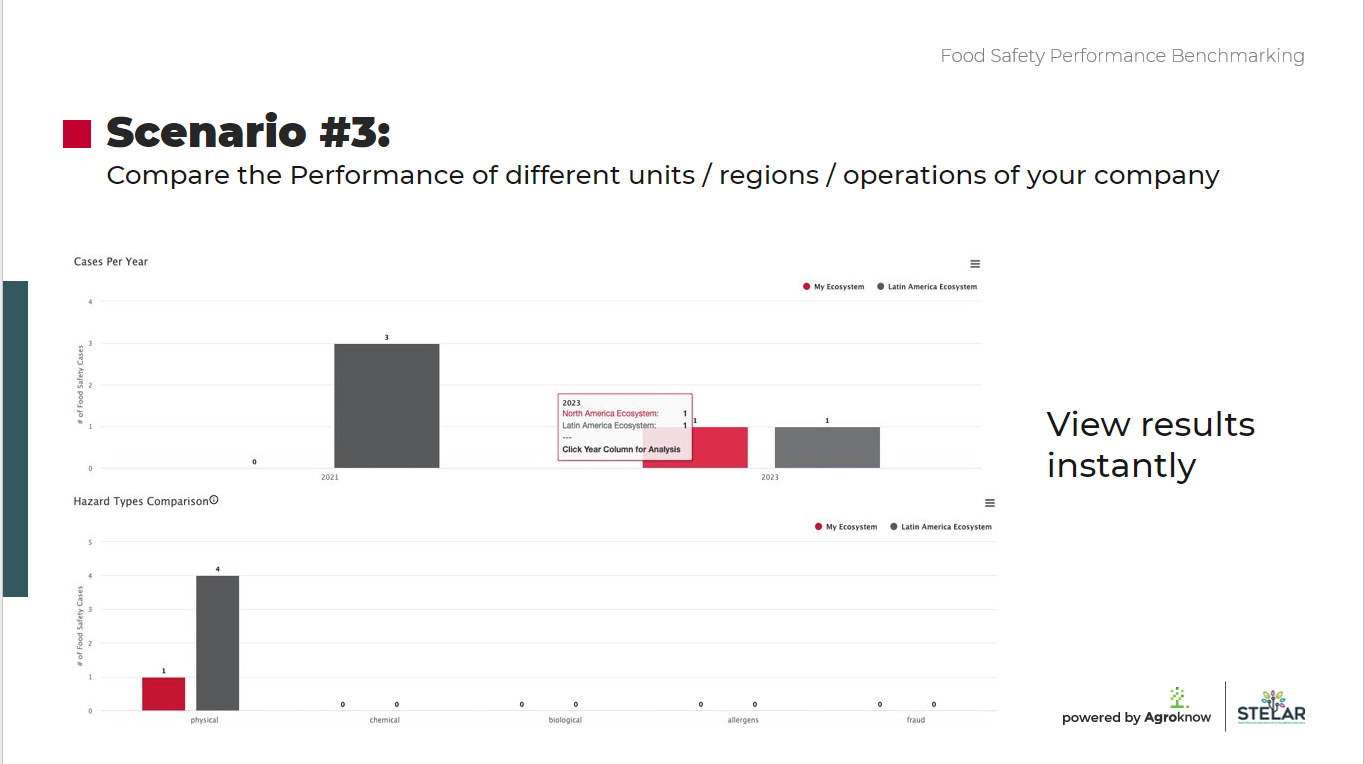

Compare the performance of different Units/Regions/Operations in your company

Finally, food & beverage companies can use the module to measure the food safety performance of their various subsidiaries, brands, units, regions and operations. By creating ecosystem lists pertaining to different regions, units or operations they can perform food safety performance benchmarking for different regions, units or operations of the company (e.g., comparing the North American and Latin American regions) to see the cases/incidents per year as well as the hazards types corresponding to these.

Additionally, in all three scenarios mentioned, food & beverage companies can have a total comparative view of food safety performance of their company and competitors by discovering important performance metrics (KPIs) for the incidents/cases recorded of the last 12 months as well as their trend. To dive even deeper into their performance evaluation they can view the Critical cases for their company and/or competitors through analytical information such as the Hazard Type, Ingredient Type, Countries Involved, Suppliers all easily shareable across the various teams.

For the full discussion, watch the video below.

Want to see FOODAKAI in action and compare your food company’s food safety performance against 2 of your competitors for a specific industry? Then start here.

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme STELAR (Grant Agreement Number 101070122). Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Commission-EU. Neither the European Union nor the granting authority can be held responsible for them.

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme STELAR (Grant Agreement Number 101070122). Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Commission-EU. Neither the European Union nor the granting authority can be held responsible for them.