“AI can help compile the large amount of data available around…. but also create patterns and predict what could happen”

As the food safety threat landscape becomes more and more complex it is vital that we remain continuously updated with what the greatest challenges are for food & beverage companies worldwide. By truly understanding what these challenges are, where they lie, we can begin to consider how we can tackle them and effectively drive innovation in the industry.

For this reason, we thought it necessary to have a discussion with professionals at heart of the industry, food safety leaders of large food beverage and manufacturing companies in order to:

- shed light to what these challenges are,

- understand what’s needed in order to tackle them,

- see how technological advances and AI can help strengthen food risk prevention,

- and highlight the biggest blockers where it comes to adopting such technology.

Valérie Sieurin, Chief Quality Officer at Unilever, was one of the first people that came to mind for discussing such critical issues. With more than 30 years of experience in world-leading food manufacturing companies, Valérie, who joined Unilever in 2022, is a proven global leader in food safety. She is an advocate of innovative and creative solutions that can be integrated into the company’s products and ensure the company remains future-ready.

A few weeks ago, we had the pleasure of having a discussion with Valérie about the biggest challenges regarding food safety in the industry.

In our discussion, Valérie highlighted the challenges food & beverage companies face regarding identifying where food safety risks lie, new sources of risk, the changes in regulations, as well as global scale traceability. In addition, she shared her dream about the implementation of AI and predictive analytics and the biggest blockers when it comes to adoption of these technologies in the industry.

Valérie, what are the biggest challenges you are currently facing regarding food safety?

We are facing challenges everyday regarding food safety. This is why our day-to-day focus is on continuously implementing and improving our HACCP plans for microbiological, foreign matters, chemicals contaminants and the allergens risks. And as much as we can, we want to manage them by design:

- either via formulation, with for example pH level or water activity not allowing pathogens to grow,

- or with technologies which detect the hazards 100% of the time. It could be, for example, automatic batch control for allergens, or vision system to ensure that we use the correct label to inform the consumer properly.

However, as of today, we don't have technology or solutions that are sufficiently developed to risk assess and achieve 100% automatic detection of every hazard present in our value chain.

When it comes to specific challenges, two hazards come to mind: emerging chemical contaminants and the presence of pathogens in new food sources.

Regarding chemical contaminants, we face many challenges:

- the list of banned chemicals that have low level of presence in the food products in general have increased in the past years and will continue to increase due to advances in science, our increased analytical capabilities and they will be included into new regulations. This, of course, is very positive as our consumers are more protected.

- The complexity of the global supply chain makes the traceability exercise more difficult: we need to have complete control over our supply chain from source to manufacturer and distribution.

- The cost of testing of chemical contaminants is high and testing is not in real time. This is the challenge: we can't implement Quality control; we need to have a Quality Assurance strategy and technology must help us.

Contaminants is an open topic where we need to find and create solutions to ensure that we are not only compliant but also anticipate what will come in the future.

The second example is about pathogens. While we do know the microbiological hazards, the pathogens and their sources, in the recent years we've seen these hazards in food sources we were not used to. For, example, we saw salmonella in raw materials or in conditions, where it was growing that led to large recalls. This is a new type of food safety risk that we need to adapt to.

And finally, climate change is bringing new Food safety challenges which could go from concentration of chemicals to shortage of supply which could generate food fraud.

What can be the impact of Artificial Intelligence (AI) and predictive analytics in strengthening food safety management systems?

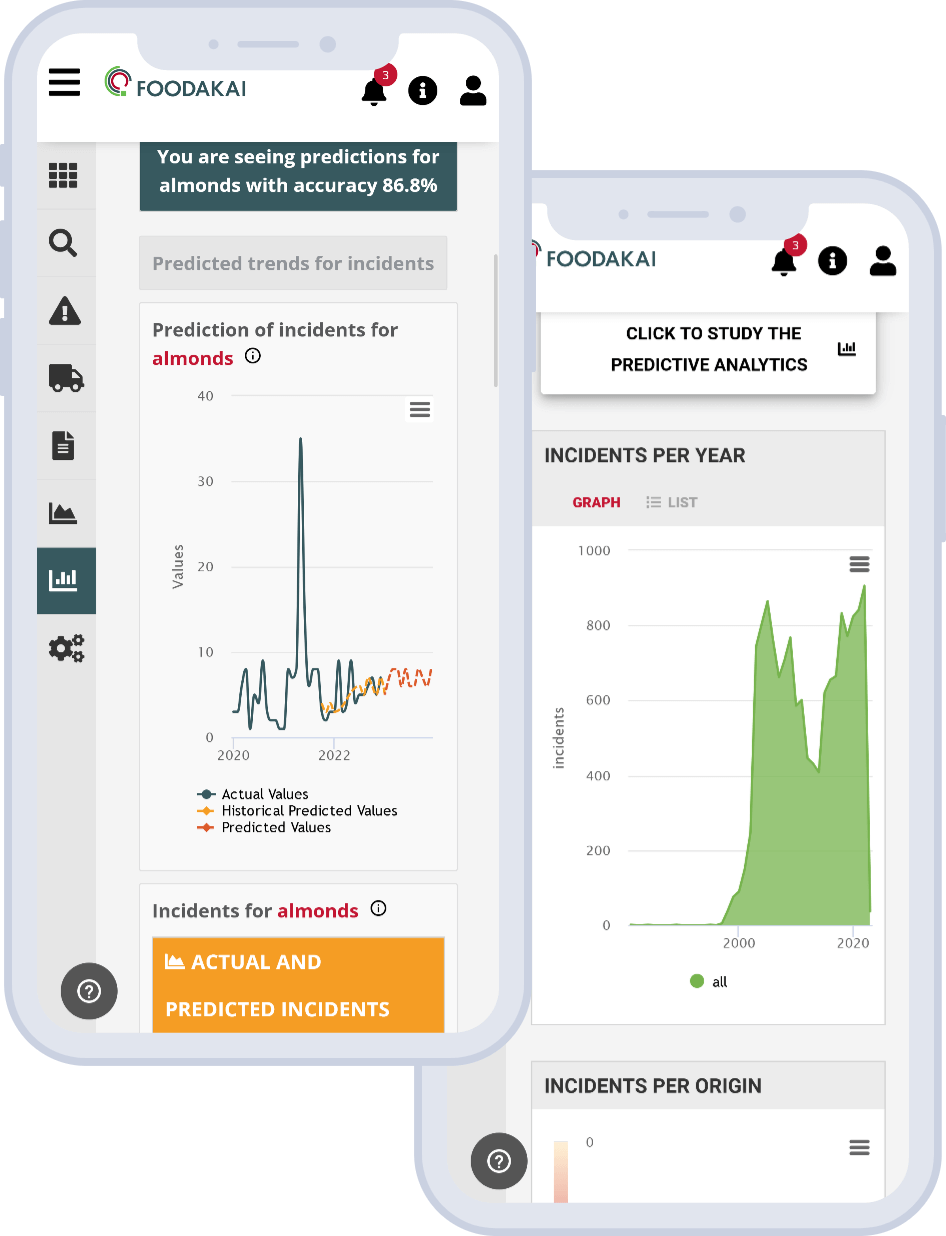

AI and predictive analytics can process and manage a high quantity of data at high speed from many sources. AI will give us solutions to manage our food safety challenges. Some known, some to be invented.

Today, AI can provide the data to feed our internal decisions regarding hazards. AI can help compile the large amount of data available outside and inside our company that we are not able to do ourselves but also create patterns and predict what could happen. Targeting the risk, sharing patterns, so that we can decide whether to include in our HACCP plan.

This will be very helpful, and I know it is possible today and we can certainly amplify the use of those solution. But the new territory for me is to apply AI directly on HACCP planning.

As you know, the process of building an HACCP plan is the following: we look at the supply chain, we identify where the risks are present, and we formulate mitigation actions. And for each change (either a new supplier or a new formulation or a new machine…), we need to review the HACCP plan. My dream is that the HACCP plan could be built by AI with the validation of food safety professionals first. AI and predictive analytics can feed HACCP plan with insights, I think this is within our reach.

What are the factors that currently slow down/impede the widespread adoption of AI and Predictive Analytics in food risk prevention?

The first factor, for me, that impedes the adoption of these technologies is the digital savviness of the people working in food safety.

Are our food safety teams well-trained in digital solutions? Do they understand and trust these solutions? Do they think that predictions are based on enough data and trusted data? Do they trust the predictions?

The second factor is that AI and Predictive analytics need to cover more field of Food safety risks and need to be simpler to use. The insights provided by these technologies are not always easy and clear to understand. I believe that there is a level of development for such solutions that can go further, in order to democratize the insights.

We need to embed AI and predictive analytics in the way Food safety professionals work, as many years ago, HACCP was embedded.

We need to democratize both. Support the increase of technical upskilling in food safety teams as well as create tools are simple enough and immediately useful to users.

The third factor is the collaboration between companies throughout the entire value chain, making data available. Greater data availability will contribute to better training of AI and Predictive Analytics. The whole industry will be safer and will benefit from the opportunity created to make food even safer.

Want to receive helpful food safety intelligence in your inbox?

Funding for this research has been provided by the European Union’s Horizon Europe research and innovation programme EFRA (Grant Agreement Number 101093026). Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Commission-EU. Neither the European Union nor the granting authority can be held responsible for them.

Funding for this research has been provided by the European Union’s Horizon Europe research and innovation programme EFRA (Grant Agreement Number 101093026). Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Commission-EU. Neither the European Union nor the granting authority can be held responsible for them.