Could the industry have prevented the elevated levels of lead in applesauce using AI?

Last month, headlines were made about the outbreak of lead poisoning traced in applesauce products that resulted in more than 202 cases being reported, primarily children 6 and younger, that showed elevated levels of lead in their blood. The outbreak, which spread at least across 33 states in the US, according to FDA’S investigation, impacted markets outside the country, Cuba and the United Arab Emirates where the affected products were also distributed. Federal testing concluded that the recalled applesauce products contained 200 times the safe for consumption amount of lead.

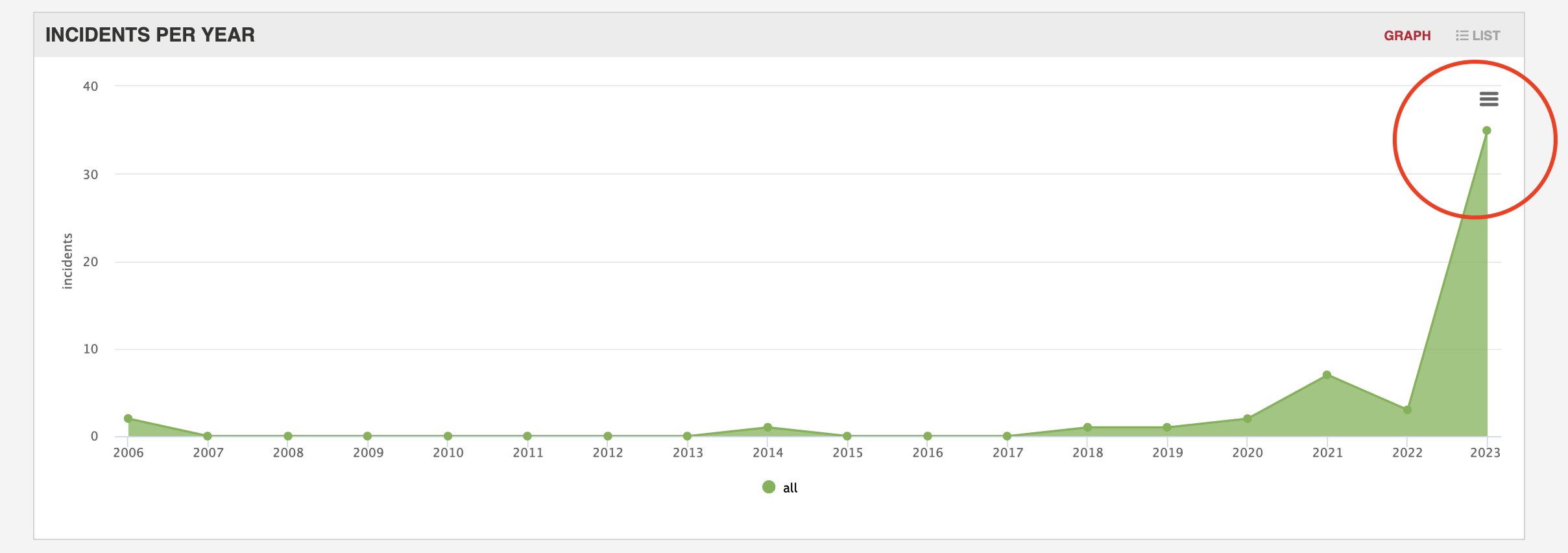

This sharp increase in the number of incidents is clearly depicted below for 2023, as it was captured by the FOODAKAI, AI-powered food safety analytics platform.

Lead poisoning can be harmful to humans of every age due to its toxicity with children being particularly susceptible, and potentially resulting in long-term problems including brain damage and developmental disorders.

The source of the elevated levels of lead in the applesauce was traced by the FDA to cinnamon imported from Ecuador which was used for its production and contained increased amounts of lead. Consequently an import alert for cinnamon products from Ecuador was placed blocking entry to relevant products in the country.

When a food safety incident of such magnitude happens, it is critical that we ask ourselves two vital questions. Could it have been prevented and why did we miss it?

Was the lead poisoning preventable?

According to Frank Yiannas, Deputy Commissioner for Food Policy & Response at FDA, as he notes in his recent article “this tragic incident was foreseeable, preventable, and is unacceptable.” The potential occurrence of such alarmingly-high levels of lead in spices shouldn’t have been a surprise but a “reasonably foreseeable hazard” to manufacturers as he states.

He continued that there is a well-documented literature regarding lead in various spices if sourced from unscrupulous suppliers and that concerns have been widely publicized about lead in infant and children’s products even by political leaders. Additionally he explained that the 2011 FSMA passed by the US congress was based on HACCP which emphasized an all-hazards approach.

With that in mind we thought it necessary to pose the same question to ourselves and see if FOODAKAI, Agroknow’s AI-powered food safety data analytics and trend forecasts platform anticipated such an event.

Did FOODAKAI forecast the lead poisoning food safety incident?

To understand if FOODAKAI had forecasted the increase of lead in cinnamon we examined the trend forecasts for the months previous to the outbreak of lead in applesauce due to imported cinnamon from Ecuador.

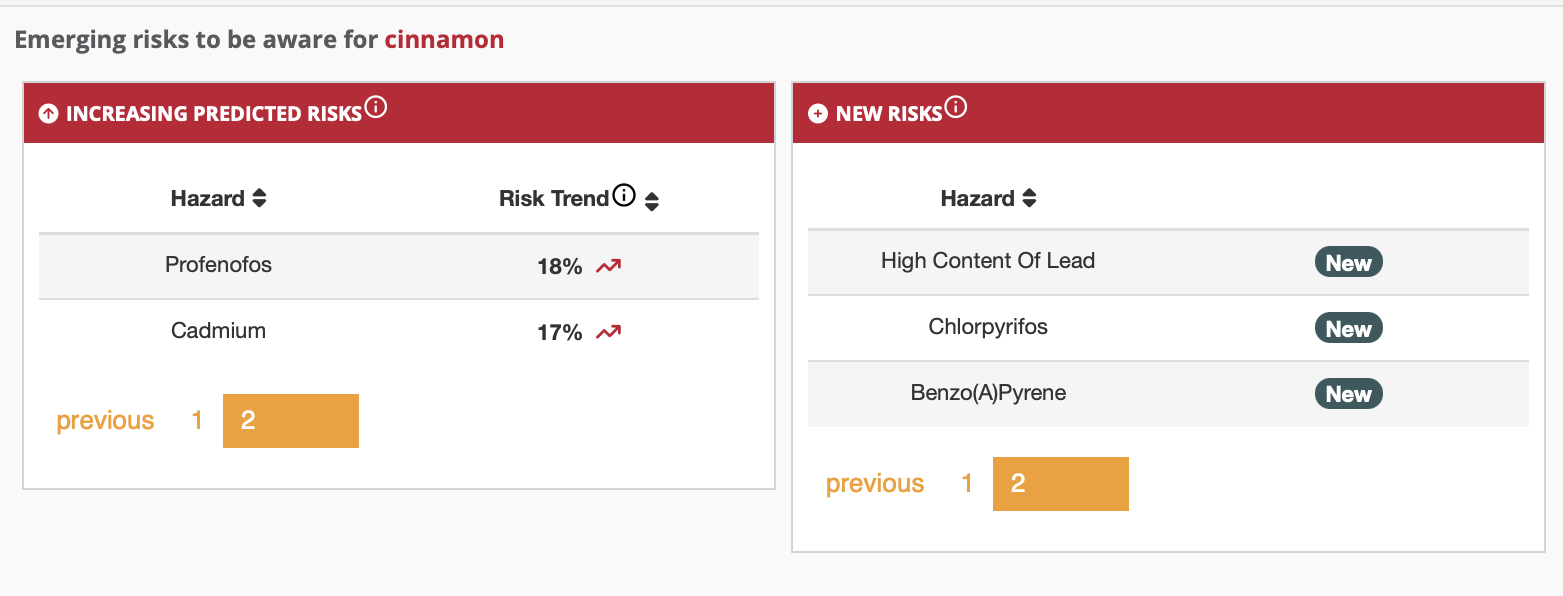

As indicated in the image below, for several months before the food safety incident, FOODAKAI was highlighting heavy metals as an emerging new risk for cinnamon. More specifically, FOODAKAI’s Tailored predictions dashboard for Herbs and Spices forecasted high content of lead in cinnamon as a prominent hazard for cinnamon. FOODAKAI was successful in forecasting the risk of lead in cinnamon, effectively helping organizations be more vigilant about this particular risk by performing a more informed risk assessment.

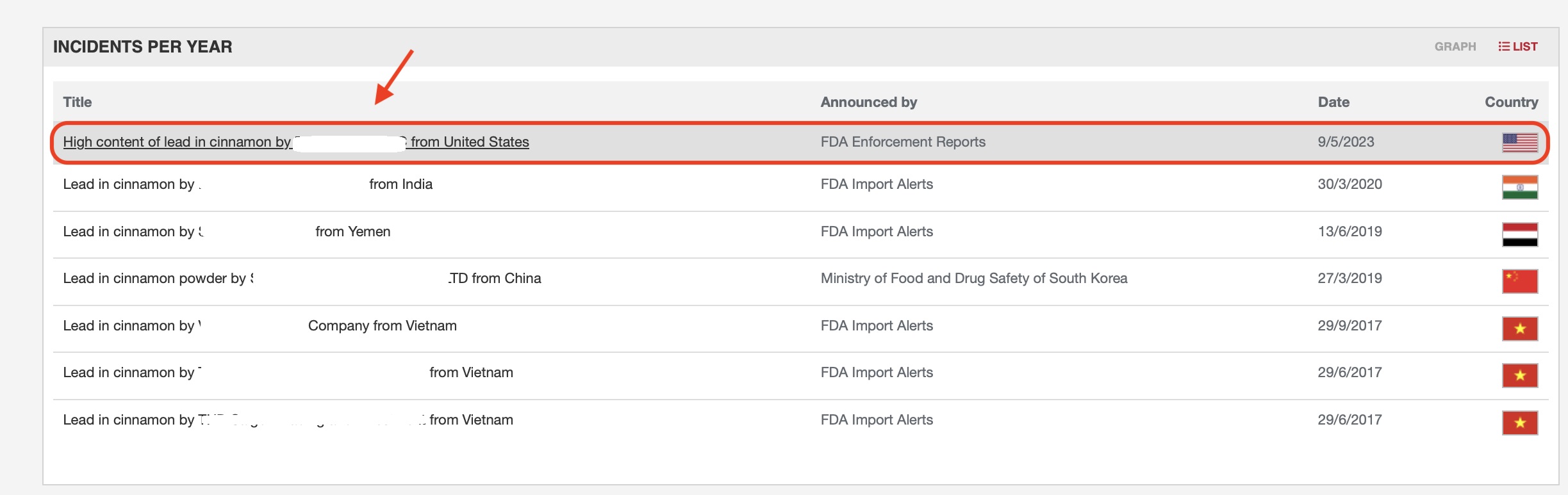

Incidentally, according to FOODAKAI, several food safety incidents pertaining to lead in cinnamon were reported by the authorities over the last years, the latest of which 6 months before the outbreak in May 2023 by the FDA in the US (as seen below).

Despite the multiple early warnings regarding lead in cinnamon it seems that manufacturers had largely missed them, not testing for lead in their products, possibly lacking an accumulated view of the number of relevant past incidents and the emerging risk.

What is the reason that the industry missed such warnings?

What has been evident in recent years is that the food industry and especially medium and smaller companies do not always include chemical hazards when formulating their risk prevention plan. Maria Velissariou, Ex-Corporate R&D VP and CSO, Mars and Founder of Maria Velissariou Consulting LLC, in a recent discussion we had with her highlighted that issue, where these food & beverage companies are already overwhelmed by focusing on microbial hazards, that they don’t emphasize on chemical hazards.

Frank Yiannas in his article similarly pointed out the presence of “narrower mindset that separates, compartmentalizes, and creates silos of hazards and risks (microbiological vs chemical), thereby, all potential hazards are no longer thought of as being part of FSMA.” This as he explained can result in a less holistic view, with food manufactures performing “less than adequate risk assessments”.

Way Forward

It is vital that food & beverage companies don’t overlook the clear signs of the risks that chemical hazards pose for their supply chain, adopting an all-hazard risk assessment approach that capitalizes on anticipating risks from all potential hazards that might impact their supply chain and endanger consumers’ health.

FOODAKAI’s successful forecasts on the lead chemical hazard is based on the development of a very elaborate taxonomy of chemical contaminants in alignment with the CAS classification of chemical hazards and AI models built on highly-tested algorithms. Through our platform's capabilities, food and beverage companies can through actionable data and accurate trend forecasts perform enhanced risk assessment on all potential chemical or other hazards factoring in emerging risks. Thus, with an arsenal of high quality food risk intelligence information, they can formulate a comprehensive mitigation strategy, take the appropriate preventive measures and avoid such large scale incidents.

Want to see how you can benefit from such forecasts? The arrange a call here.

Want to receive helpful food safety intelligence in your inbox?