Thinking inside the box…migration from packaging materials to our food.

Some have described it as the “holy grail” of analytical food science. The ongoing goal is for the development of a universal, non-destructive, precise, and sensitive enough analytical method for the determination of substances that can migrate from packaging materials to our food. It’s not an exaggeration to say that a high proportion of the scientific community has turned their gaze to the development of such a technique that can successfully qualify and quantify all chemical compounds that may end on our plate and have potentially adverse health effects.

Food packaging migration

But why is there so much interest regarding the determination of these compounds? Consider that food packaging's purpose is to provide food product safety, easy handling, and transportation by preventing chemical contamination and enhancing shelf life, providing convenience for consumers. Ironically, the same material that provides food safety, acts as a source of possible chemical contamination of the food. When there is direct contact between the packaging material and the food product, possible migration of chemical compounds into a food can occur, depending on factors such as the nature of the packaging material, the duration and temperature of storage, the physicochemical properties of the migrant, and the type of food product, as reported in M.S. Alamri et al.

Food contact packages are made from a variety of materials including plastics, rubber, paper, and metal. The materials must be manufactured in compliance with regulations so that any potential transfer to foods does not raise safety concerns. However, some of the chemicals used in the production of packaging materials and migrating into the food matrix may be harmful if they enter the human body and are consumed in large quantities, according to EFSA. For example, certain plastics used in food packaging may contain bisphenol A (BPA) which is known to disrupt hormone function and has been linked to health problems such as obesity, diabetes, and cancer.

Intentionally (IAS) and non-intentionally (NIAS) added substances

Among the various types of food packaging, migrating compounds are printing inks, adhesives, plasticizers (mostly phthalates), thermal and UV stabilizers-photoinitiators- (such as benzophenone), slip additives, antioxidants, monomers and oligomers, metals such as tin, lead, aluminum and chromium and the highly toxic organic compounds such as polybrominated diphenyl ethers, polychlorinated biphenyls, perfluoroalkyl, and poly-fluoroalkyl substances, even nitrosamines from waxed cardboard surfaces.

These contaminants are distinguished into intentional (IAS) and non-intentionally (NIAS) substances. IAS is added to the packaging material to improve the packaging's properties, enhance its appearance or functionality, or extend its shelf life. Most plasticizers, antioxidants, and stabilizers are considered as IAS. On the other hand, NIAS are not deliberately added to the packaging material but are present as impurities or by-products of the manufacturing process. NIAS can arise from a wide range of sources, such as starting materials, additives, or processing aids. Examples of NIAS include styrene, acrylamide, lead, cadmium, some bisphenols, polychlorinated biphenyls, etc.

Health-related Risks and Regulations

As said before, contamination of food by migration substances is related to potential health risks. However, this is still a subject of much debate due to the lack of information. The presence of carcinogenic, toxic, or mutagenic compounds in the packages doesn’t necessarily imply their partial or total migration to food, nor the activation of their mechanisms of toxic action, after entering the organism.

Regulatory agencies and authorities set limits on the amounts of certain chemicals that can migrate from packaging materials into food to ensure food safety. The European Legislation on Food Contact Materials is based on Regulation (EC) No 1935/2004, which establishes the general requirements for food contact materials and the authorization of new substances. Furthermore, specific requirements concerning only plastic materials are set forth in Regulation (EC) No 10/2011. According to this regulation, the Overall Migration Limit (OML) is set at 10 mg of substances per dm² of the food contact surface, for all substances of the plastic material. Also, Specific Migration Limits (SML), between 10 and 50 μg per kilogram of product (ppb) are established for some individual authorized substances, when the absence of mutagenicity has been proven. Migration levels above 50 ppb are allowed when a substance has been fully evaluated and approved. Potentially carcinogenic and genotoxic substances must not migrate at all.

FOODAKAI reports

FOODAKAI database can give us a glimpse into incidents of migration from food contact materials. In the period between April 2020 and April 2023, 396 migration incidents were reported worldwide. Notifications concerned either the excess of OML and SML or the presence of unauthorized compounds in the material.

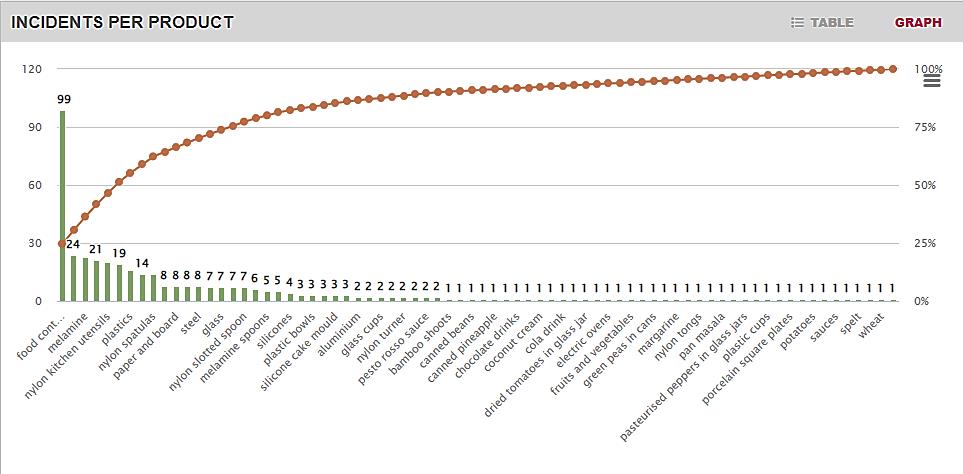

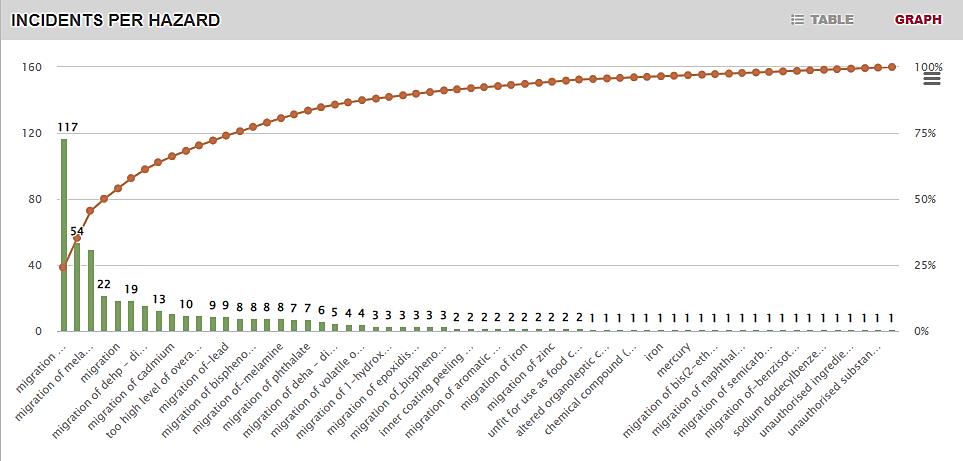

Ninety-nine incidents were about food contact materials in general, 24 about melamine (without further specifications reported from authorities), and 21 about nylon kitchen utensils, while the rest of them were mostly about various plastic products and some food categories (see Graph 1). Migration of primary aromatic amines, formaldehyde, and melamine migration was reported in most cases, as shown in Graph 2. Few were the incidents of heavy metals migration, mostly cadmium, and lead, while the rest of them concerned the presence of volatile organic compounds.

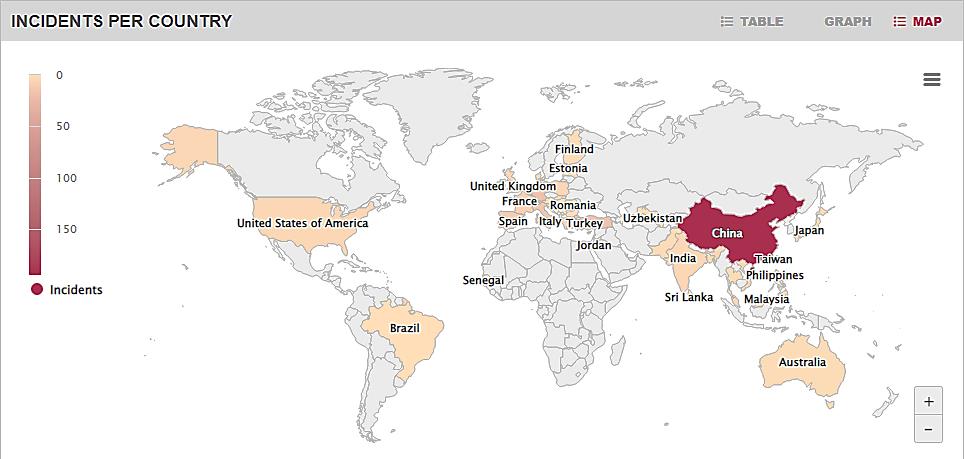

The vast majority of products, 197, originated from China, 19 products from Germany, and the other 19 were of unknown origin. Sixteen products were from Turkey, 15 were from Luxemburg, and 14 were from Italy and Belgium. Countries with less than 10 incidents per product are also shown in the following Photo by FOODAKAI. In most cases, incident type led to border rejection of the product.

Analytical aspects

As mentioned in the beginning, the development of an analytical method for the targeted monitoring and successful determination of compounds of interest is considered the “holy grail” of analytical and food chemistry. Nowadays, the overall migration of substances into food products is measured with food simulants, not actual foodstuffs. There are specific guidelines on testing conditions for materials in contact with food. Food simulants are used as substitutes for food due to the simplification of chemical analysis. There are several food simulant types being used, based on the physicochemical properties of the food that we want them to mimic, at desirable thermal and humidity conditions. Most types of simulants are a mix of ethanol and water or acetic acid and water, in various proportions, as described by Marinella Vitulli, Laboratory Manager, in the detailed article of New Food Magazine. For dry foods testing, the simulant used is a synthetic polymer with a defined pore size (trade name “Tenax”).

Overall migration might give us an approximation for actual migration into food but doesn’t specify the substances that migrate to the food. And here lies the analytical problem; the lack of selective and sensitive enough methods for the precise determination of every substance that may migrate to the food. Many substances still remain unidentified or even undetermined, today. Researchers estimate that there are over 12,000 known chemicals used in the manufacturing of food contact materials, while a significant number of NIAS remain largely unknown. Several targeted and untargeted screening techniques, mostly chromatographic techniques, are used for safety evaluation. GC-MS/FID, headspace GC/MS, and LC-QToF-MS are used for the determination of organic substances, and ICP-MS for trace elements and metals. After their determination, their identification is mainly done using databases, relevant literature, in-house knowledge, and available data concerning the starting materials. Of course, this way of identification raises problems regarding method’s trueness, precision, robustness, and reproducibility. These terms might sound unfamiliar and confusing, but they actually are the core of an integrated analytical method. A piece that is still missing from the migration-food safety puzzle.

The individual case of PFAS

Perfluoroalkyl and poly-fluoroalkyl substances (PFAS) are a group of chemicals used in cookware, food packaging, and in food processing for their non-stick and grease/oil/water-resistant properties. Packaging made with PFAS often resembles paper or cardboard. As their molecules consist of a carbon-fluorine bond, they are considered as strong compounds that do not easily degrade and one of the most dangerous compounds that migrate to food from packages, as indicated in the article by Kevin Lora in Consumers Report. Human exposure to PFAS has been linked in many studies to multiple health effects. Certain PFAS are toxic for reproduction and others may cause cancer in humans. Some PFAS are also suspected of interfering with the human endocrine system.

For the protection of human health, the European Food Safety Authority (EFSA) set a safety threshold for the main PFAS that accumulate in the body: perfluorooctanoic acid (PFOA), perfluorooctane sulfonate (PFOS), perfluorononanoic acid (PFNA), perfluorohexane sulfonic acid (PFHxS), back in 2020. From January 1st, 2023, Regulation (EC) 2022/2388 came into force, regarding new maximum levels of presence of the above PFAS, in various food categories.

What makes PFAS cases challenging is that they are amphiphilic; they are as much lipophilic and hydrophilic at the same time. That property makes their analytical determination difficult and questionable. As far as the overall migration, we can’t predict which simulant is the most suitable for a successful mimic of their migration. Another challenge is that these substances are often present at very low levels, and can be difficult to distinguish from other substances that may be present, leading to false results. In addition, different PFAS compounds have different physical and chemical properties, which can affect their behavior in different food matrices, thus their determination. It’s no coincidence that currently there is no standardized method as a guideline for the analysis of all PFAS compounds in food matrices. Hence, their contribution to migration issues cannot yet be precisely assessed.

What is next?

Even if there are still a lot to cover and obstacles to overcome in the matter of migration from packaging materials, the efforts of agencies such as the FDA and EFSA to review new scientific information, assess the risk deriving from food contact substances and ensure food safety are worth mentioning. Risk assessment studies and screening monitoring programs are a necessity for a holistic comprehensive regulatory strategy.

As the final responsibility for the compliance of food packaging lies with the seller of the packed food and not the manufacturer of the packaging, food companies should look for reliable producers. Safety trends and future food safety prospects dictate the use of innovative raw materials, coatings, and post-consumer recycling additives to produce more and more ecological and safe packaging. New technological achievements, like the integration of nanomaterials in packages or the use of biopolymers, have their role to play in the foreseeable future. It’s time to think outside the box…