What can the industry learn from the 2023 Cantaloupe Melon Outbreak? Examining AI’s preventive potential

Late last month, the Public Health Agency of Canada provided their final update on the nationwide Salmonella outbreak linked to cantaloupe melons that resulted in 9 deaths and 68 hospitalizations. In the US, according to the concluding report of the CDC, the multistate outbreak resulted in 158 hospitalizations and 6 deaths. Laboratory data analysis showed that it was the same Salmonella strain that caused the illnesses in both countries.

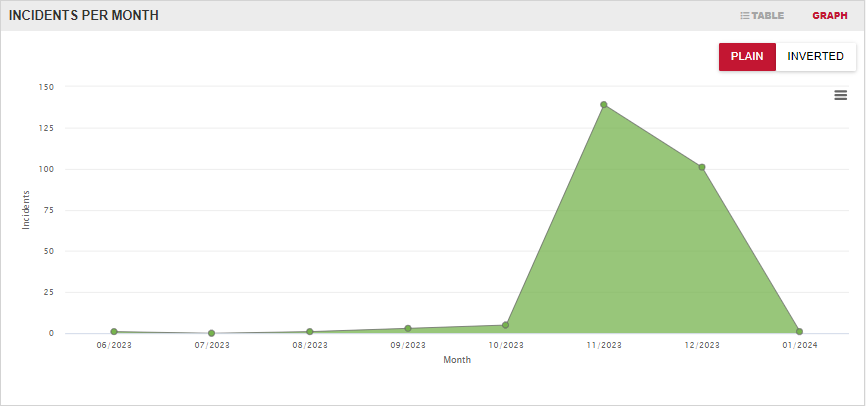

The steep rise in the number of incidents concerning cantaloupe melons during the last couple of months is illustrated in the below diagram, as captured in FOODAKAI.

Salmonella as the source

While anyone can get infected from Salmonella, most people will recover after a few days without receiving medical care. However, the infection can be deadly for susceptible individuals (such as the old and the very young). The CDC notes that the true number of infections is likely much higher than reported since most Salmonella cases are self-limited and do not require antibiotic therapy.

The traceback and epidemiologic data clearly showed that it was the cantaloupe melons that were responsible for this food safety crisis. Due to the physiology of the Salmonella microorganism, and the nature of the food vehicle, one can assume that the issue likely stems from surface contamination, probably due to not adhering to cleaning and sanitation SOPs. Considering that this is a recurring issue, as another major outbreak of Salmonella Typhimurium occurred in the summer of 2022, and once again cantaloupe melons were implicated, it is evident that something needs to change. Moving from reactivity to proactivity

Rather than trying to identify the exact cause behind these outbreaks, which can be a difficult task given the complexity of the food chain, change should start with how suchcrises are being approached; The food industry should start by adopting a more proactive approach and search for pioneering ways to improve prevention strategies.

Recognizing the critical role that a thorough Hazard Analysis plays in preventing food safety crises and actively working to enhance it with advanced technologies, is the first step towards following a risk-averse prevention strategy.

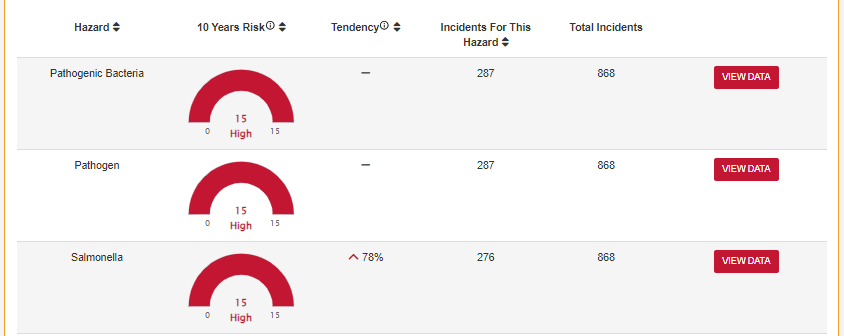

FOODAKAI allows food & beverage companies to conduct a dynamic Hazard Analysis for any raw material and/or finished product, that continuously adjusts based on real-time information and data. To examine this, FOODAKAI was utilized in order to perform Hazard Analysis for cantaloupe melon. As seen from the image below, Salmonella had been reported as a High-Risk Biological Hazard for cantaloupe melons over the past year, with a reported increased tendency of 78%.

FOODAKAI was therefore successful in highlighting the ongoing risk associated with Salmonella contamination in cantaloupe melons. This could have been used as a warning sign for food safety professionals to focus more on proactive measures. For example, it could have prompted them to conduct a more detailed assessment of the food safety practices that relevant suppliers were following, by requesting additional information or even by scheduling a series of unannounced audits to their premises. They could have also enhanced their internal testing protocols or requested the guidance of food safety authorities to mitigate the risk.

Even though FOODAKAI did not predict this outbreak, it recognized the elevated risk of Salmonella in cantaloupe melons, and this could have allowed for timely and strategic interventions.

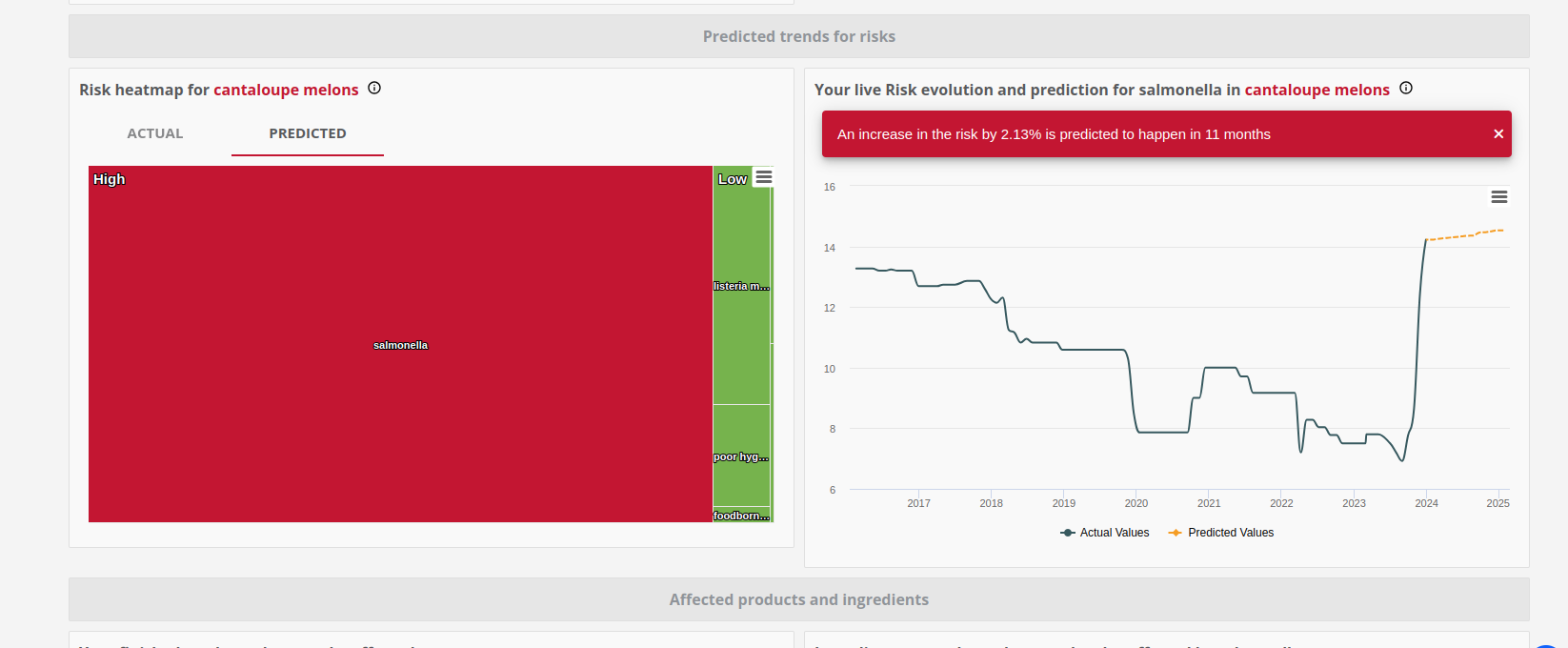

Looking at the risk evolution as well as the prediction forecast for Salmonella in cantaloupe melons in the image below, it can be seen that Salmonella is forecasted as a high risk for this product category for next year as well.

An emphasis on prevention has become more imperative than ever for food safety professionals. In order to prevent more outbreaks and recalls, food and beverage companies should develop and follow a robust risk mitigation strategy while leveraging high quality food risk intelligence data.

FOODAKAI offers detailed overview of all historical food safety incidents for all products as well as hazard types and risks associated with the product for complete coverage. With forecast trends on future incidents and risk performance tracking of every supplier, food & beverage companies can prioritize interventions whenever deemed necessary, effectively enhancing risk mitigation strategies.

Want to see if you can elevate your critical risk monitoring & assessment, factoring in unforeseen risks? Then book a demo.

Want to receive helpful food safety intelligence in your inbox?

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme ΤΙΤΑΝ (Grant Agreement Number 101060739). Funded by the European Union. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.

Funding for this research has been provided by the European Union’s Horizon Europe innovation programme ΤΙΤΑΝ (Grant Agreement Number 101060739). Funded by the European Union. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.