What does the future hold for chocolate?

Based on the recently published report about the lessons learned for chocolate products, we took a deep dive into the food safety data insights. The goal is to evaluate the impact of this challenging period on the global supply chain. The pandemic has brought turbulence for the last months in the agri-food supply chains, but is this reflected in the latest food recalls and border rejections?

Cocoa: The impact of the pandemic

According to FAOSTAT data, Africa is the largest cocoa-producing region in the world and there are more than over 150,000 confirmed cases[1] of coronavirus across the continent.

The chocolate supply chain usually starts from the following countries: Ivory Coast, Ghana, Indonesia, Nigeria, Cameroon, Brazil, and Ecuador. Spanning three continents, the production of the most important raw material for chocolate production is currently contending with the impact of COVID-19.

The challenge of the virus is two-fold for the cocoa and chocolate supply chain. On the one hand, it relates to supply chain continuity as various modules within the food industry now require urgent reassessment to safeguard production. From assessing new potential suppliers to re-evaluating the critical points of control and exploring alternative options in ingredient supply, this period is very challenging for the global chocolate industry. COVID-19 has caused disruption to the processing of cocoa beans, driving global chocolate players to consider alternative routes for building stability in their trading.

On the other hand, analysts claim that COVID-19 may bring a spike in recalls during the second half of 2020, as many manufacturers are seeking to replace ingredients and/or make changes to their suppliers. Recently, the US FDA announced[2] a flexible policy for certain labeling deviations in foods. This could lead to border rejections if an export country is not aware that a deviation is permitted in the country of origin, or might lead to potential fraud issues.

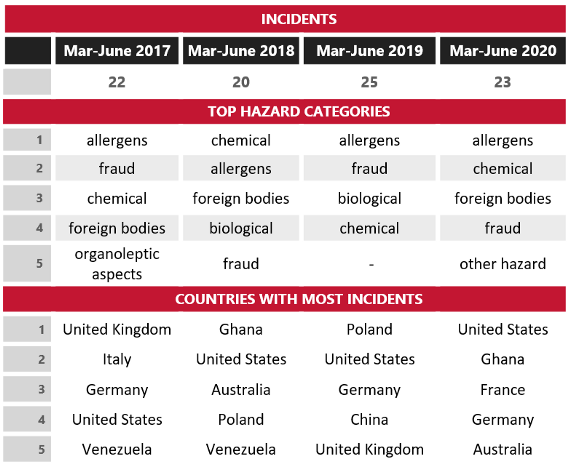

According to FOODAKAI data insights, the latest data shows that recalls and border rejections that took place from March to June 2020 are at the same levels for the last 3 years. The products that were produced during the pandemic, will start to reach the shelves of retailers in the weeks to come, so we will definitely keep an eye on upcoming food protection incidents. As for the top hazard categories, fraud remains a low threat for cocoa and chocolate products.

The global regions most at risk

According to data from the last 3 years, Africa, South America, and Asia are the largest cocoa-producing regions with the most prevalent chemical hazards. Across these three regions, chemical hazards in Asia account for 40% of the total cocoa-related incidents, while in Africa and South America, the incident rate is much higher standing at 70% and 95% respectively.

Within Africa, food recalls and border rejections are due to chemical hazards, with pesticides such as organophosphate, neonicotinoid, pyrethroid, and organochlorine being the four out of the top five hazards for cocoa produced in this region.

In South America, chemical hazards in the form of 2,4-dinitrophenol (DNP), pyrethroid, and heavy metals such as cadmium and anilino-pyrimidine fungicide are the top-ranking hazards for South American cocoa.

The same as above applies to the Asia region, where the top hazard category for this region is chemical hazards. The major chemical hazard in Asia is 2,4-dinitrophenol (DNP), followed by Aflatoxin, Salmonella spp., and fraud (spoilage).

If we take into account the COVID-19 environment, there are regions that are more vulnerable due to an increase in active cases. For example, Brazil has the 6th biggest cocoa-producing country in the world, and active COVID-19 cases are skyrocketing (526,447 cases) which could have implications for the production and processing of cocoa. Meanwhile, India shows an increasing tendency in active cases (198,706 cases), which can also be a very real threat to the cocoa supply chain.

What does the future hold for chocolate?

It’s clear that from what we have outlined above, the ability to predict what will happen in the cocoa and chocolate global supply chain is crucial to ensure the longevity of chocolate businesses in the future. This can only be done with access to intelligent data insights, especially relating to the situations that could bring about major disruption.

Based on recent studies[3], it has been predicted that there will be an increase in recalls and border rejections for cocoa and chocolate products, with an increase by +8% compared to 2019 incidents. While it is predicted that incidents surrounding cocoa as the major chocolate ingredient will increase slightly in 2020, there are other ingredients in the chocolate supply chain that have the potential to increase chocolate recalls dramatically. According to prediction algorithms, there will be a significant increase in the recall of nuts, and especially peanuts, almonds and hazelnuts during 2020, with an upward trend of +30% compared to 2019.

It is very important that in these uncertain times, the global supply chain remains unharmed. Data insights play a major role in predicting the potential threats and guide the lab analysis during production — ensuring that the critical aspects of safety and quality are not being overlooked. Prevention is key, so it is essential that the quality and food safety professionals harness the power of algorithms to ensure that attention is put to what matters the most. The chocolate and cocoa supply chain is a diverse ecosystem spanning across the globe. A break in one part of the chain can have major implications to the safety and availability of chocolate products in multiple countries.

Get the raw data and further food safety data insights on the food industry through FOODAKAI the food safety intelligence platform.

[1] John Hopkins University and Africa Center for Disease Control (accessed 02/06/2020)

[2]https://www.fda.gov/food/cfsan-constituent-updates/fda-announces-temporary-flexibility-policy-regarding-certain-labeling-requirements-foods-humans

[3] Polychronou, I., Katsivelis, P., Papakonstantinou, M., Stoitsis, G., & Manouselis, N. (2020, February). Machine Learning Algorithms for Food Intelligence: Towards a Method for More Accurate Predictions. In International Symposium on Environmental Software Systems (pp. 165–172). Springer, Cham.

“Funded with the support of European Commission, and more specifically the project CYBELE “FOSTERING PRECISION AGRICULTURE AND LIVESTOCK FARMING THROUGH SECURE ACCESS TO LARGE-SCALE HPC-ENABLED VIRTUAL INDUSTRIAL EXPERIMENTATION ENVIRONMENT EMPOWERING SCALABLE BIG DATA ANALYTICS” (Grant No. 825355)”